If you’ve ever wondered how to squeeze more productivity out of your day while still keeping your sanity intact, you’re in the right place.

If you’ve ever wondered how to squeeze more productivity out of your day while still keeping your sanity intact, you’re in the right place.

Today, marketing without a business plan in place is nearly impossible if you want to drive results—and it’s even more true in the manufacturing sector.

You need to align your strategy of bringing in new clients with how you’re planning to expand into new markets, work at capacity, and expand your company.

Industrial marketing can help you create a competitive strategy and drive financial success. Using techniques that work best for each business, its customers, and its leads to get people interested in products or services.

With that background out of the way, let’s dive right in and discuss more about what industrial marketing is and its impact.

——–

How To Have Big Income Without A Job.

Try Foreign Currency Trading or Forex for short. Just sharing an idea that may help you in life.

If you decided to check it out, you need an International Currency Broker. I highly recommend my own trusted Broker where I personally trade my investments. They have a current Registered Forex Trader Referral System that gives $50 free startup trading account credit to interested friends, relatives, colleagues, or acquaintances. This can greatly assist you at the start of your Global Forex Trading.

Click link below.

https://www.xm.com/referral?token=ConMfVXEe7ANgzLpx7OJjw

How Forex Trading can help you

Wish you a new and prosperous life ahead!

Thank me in the future.

We provide one stop turnkey onsite/rooftop Solar PV Installation. We turn your free space into a clean energy resource. We do all things and just give you pure power from the sun.

If interested and wish to have solar PV installation price quote for your house or business establishment, email me at gregoriojess@yahoo.com

Limited to Philippine area installation only.

This post contain affiliate links. As an Affiliate Marketer I earn from qualifying purchases. There is no additional cost to you on it.

There are lots of hacks online that can get you a better deal.

Our latest perspectives on the coronavirus outbreak, the twin threats to lives and livelihoods, and how organizations can prepare for the next normal.

Despite ongoing public-health concerns, the desire to spend and shop is palpable. This week, McKinsey published new surveys of consumers in Argentina, Australia, Brazil, Central America, and the United States, detailing the strength of the consumer urge in each country. The outlook is brighter. Consumers are less anxious and depressed about health concerns. Business executives are a bit more optimistic this month than last. And our new surveys of global B2B buyers and those in Asia and Europe suggest that confidence is holding firm.

That said, the picture these surveys paint is complex. In a sense, the world is turning from “resilience” to “return”—the third of the five pandemic elements we sketched out in late March. To get back to business, many companies are running spreadsheets to see how many people spaced six feet apart will fit in an office, planning one-way paths through the workplace, and figuring out adaptations to restrooms, lunchrooms, and entrances. All of those are critical tasks, but they are not enough. What’s needed is a return “muscle”: an enterprise-wide ability to absorb uncertainty and incorporate lessons into the operating model quickly.

—

—

—

This post contain affiliate links. As an Amazon Associate I earn from qualifying purchases. There is no additional cost to you on it.

Shop online at Amazon. Would be your best experience of modern day eCommerce.

World’s No.1 Online Store

https://jcgregsolutions.wordpress.com/2020/05/27/buy-anything-online-from-amazon/

—

Amazon Kindle Books Unlimited Membership. Bring your own book library wherever you go. Download millions of books on any device.

—

Protect Yourself From 2019-nCov Virus And Volcanic Ash Inhalation

Disclaimer:

There are no current vaccines, pills, potions, lotions, lozenges or other prescription or over-the-counter products available to treat or cure coronavirus disease 2019 (COVID-19). For official information and guidance, please refer to Centers for Disease Control and Prevention (CDC) website below:

https://www.cdc.gov/coronavirus/2019-ncov/index.html

In the past, we go to big and great libraries to read and research. Then the internet provided us with online browsing and search.

Nowadays, thanks to Amazon, we now can download even the most recent best sellers, periodicals, fiction and non-fiction books- online at less cost compared to the price of printed copies. Not only can we read it on our laptop PC, tablets, or smartphones, we can also listen to it if we come across “don’t feel like reading” mood.

You literally carry a library in your pocket or bag. Buy and download with a free app called Kindle. It is really an awesome tech life!

Don’t get left over by millenials filling up their coconuts through it. This is the reason why they knew so much. They are no longer printed copy bookworms. They are Kindle Book leeches. No clutter, no litters of old titles, and all the space in their quarters. They mastered “just in time” reading to create efficient living.

Check it out. You will enjoy the possibilities and the life-on-the-go without missing your favorite read.

—

This post contain affiliate links. As an Amazon Associate I earn from qualifying purchases. There is no additional cost to you.

—

Shop online at Amazon. Would be your best experience of modern day eCommerce.

World’s No.1 Online Store

https://gregoriojess4.wixsite.com/jcgregsolutions/post/world-s-no-1-online-store

—

Protect Yourself From 2019-nCov Virus And Volcanic Ash Inhalation

Disclaimer:

There are no current vaccines, pills, potions, lotions, lozenges or other prescription or over-the-counter products available to treat or cure coronavirus disease 2019 (COVID-19). For official information and guidance, please refer to Centers for Disease Control and Prevention (CDC) website below:

https://www.cdc.gov/coronavirus/2019-ncov/index.html

—

You may be interested on free samplers below:

Take a time out from your busy sched. Read a book. There are more than 25 free eBooks at Amazon. Thousands to choose from. Browse and pick today.

Stealing Power: Absolutely gripping crime fiction full of totally unputdownable mystery and suspense (Detectives Kane and Colt Thrillers Book 1)

—

Mystery and Suspense:The Tipping Point: A mystery thriller full of intrigue about greed, fraud and murder… (International Mystery: Book 1)

—

The Kimberley Secret: A Jack Rogan Mysteries Prequel

—

A Honeybun and Coffee: Romantic Suspense with a Taste of Mystery (Honeybun Heat Book 1)

—

In the Spirit of Murder (Book #1 in The Claudia Hershey Mystery Series)

—

MULTIPLE MOTIVES: A Kate Huntington Mystery (The Kate Huntington mystery series Book 1)

—

Echo: (A Kate Redman Mystery: Book 6) (The Kate Redman Mysteries)

—

Deadly Stillwater: A compelling crime thriller (Mac McRyan Mystery Series Book)

—

Cold Comfort (Bridgette Cash Mystery Thriller Book 1)

—

FORGET ME NOT – MARK KANE MYSTERIES – BOOK ONE: A Private Investigator Clean Mystery & Suspense Series. Murder Mysteries & Whodunits with more Twists and Turns than a Roller Coaster.

—

All Eyes on Me (A Miranda and Parker Mystery Book 1)

—

Loose Ends: A Private Investigator Crime and Suspense Mystery Thriller (California Corwin P. I. Mystery Series Book 1)

—

A Honeybun and Coffee: Romantic Suspense with a Taste of Mystery (Honeybun Heat Book 1)

—

ICE – MARK KANE MYSTERIES – BOOK TWO: A Private Investigator Clean Mystery & Suspense Series. Murder Mysteries & Whodunits with more Twists and Turns than a Roller Coaster

—

Mystery: Spine Break: The First Short Story (a gripping fist-fight action detective series) A Small-Town Justice Suspense Thriller: An Anthony Vico & Mitch Malory Small-Town Justice Suspense Thriller

—

His Hand In the Storm: Gray James Detective Murder Mystery and Suspense (Chief Inspector Gray James Detective Murder Mystery Series Book 1)

—

The Perfect Wife (A Jessie Hunt Psychological Suspense Thriller—Book One)

—

Father Brown (Complete Collection): 53 Murder Mysteries: The Scandal of Father Brown, The Donnington Affair & The Mask of Midas…

—

Hazardous Duty: Squeaky Clean Mysteries, Book 1: An Amateur Sleuth Mystery and Suspense Series, Christian Fiction

—

Polar Bear Dawn: A Detective Bernadette Callahan Mystery (Detective Bernadette Callahan of the Royal Canadian Mounted Police Book 1)

—

Sunset in the Mists – The Dark Draws the Curtain: Christian Mystery & Suspense Romance (The Evynsford Chronicles Book 1)

—

Ghost of a Chance (Maggie Mulgrew Mysteries Book 1)

—

If She Knew (A Kate Wise Mystery—Book 1)

—

Shackles: The truth will set you free

—

Wicked Innocents: Case No. 1 (The Frontenac Sisters: Supernatural Sleuths & Monster Hunters)

—

Amazon Kindle Books Unlimited Membership.

Bring your own book library wherever you go. Download millions of books on any device.

—

Take a time out from your busy sched. Read a book. There are more than 25 free eBooks at Amazon. Thousands to choose from. Browse and pick today.

The Universe Doesn’t Give a Flying Fuck About You (Epic series Book 1)

—

Nikola Tesla: Imagination and the Man That Invented the 20th Century

—

White Fang (AmazonClassics Edition)

—

Olivia, Mourning (The Olivia Series Book 1)

—

Leonardo da Vinci: A Life From Beginning to End (Biographies of Painters Book 1)

—

Uncommon Character: Stories of Ordinary Men and Women Who Have Done the Extraordinary

—

The World’s Greatest Books — Volume 11 — Ancient and Mediæval History

—

Historical Romances: Under the Red Robe, Count Hannibal, A Gentleman of France

—

Aging Well: Solutions to the Most Pressing Global Challenges of Aging

1st ed. 2019 Edition

—

150 Handpicked Unique Handmade Product Collection Examples for Handmade Businesses 2017 – 2018: Fuel Etsy Selling Success and the Handmade Entrepreneur (Etsy Book, Etsy business for beginners)

—

Ten Great Events in History

—

The Future of Land Warfare (Geopolitics in the 21st Century)

1st Edition

—

U Turn to the Holy Spirit: No More Fear

—

Captain Cook His Life, Voyages, and Discoveries

—

Alexander The Great: A History From Beginning To End (One Hour History Military Generals Book 1)

—

Writing a Book a Week: How to Write Quick Books Under the Self-Publishing Model. Write Free Book Series

—

Arguments Of Celsus, Porphyry, And The Emperor Julian, Against The Christians

—

Coming To Jesus: One Man’s Search for Truth and Life Purpose

—

The Assyrian Empire: Explore the Thrilling History of the Assyrians and their Fearful Empire in the Ancient

—

Into The Open Economy: How Everything You Know About The World Is About To Change

—

How To Conquer Clutter And Organize Your Home: A Room-By-Room Blueprint For Stress-Free Organization

—

101 Amazing Facts

—

Why Doesn’t God Speak to Me? (Believers’ Boot Camp Book 1)

—

Minimalism: The Path to an Organized, Stress-free and Decluttered Life

—

Keeping Well: An Anti-Cancer Guide to Remain in Remission

—

Amazon Kindle Books Unlimited Membership.

Bring your own book library wherever you go. Download millions of books on any device.

Thank you for finding my social media postings and affiliate products/solutions sensible enough to make things better. Not only for the likes and comments, but most of all, for all the “Follow” or “Subscription” which makes JcGreg Solutions already a daily companion in your life.

I promised to give you more exciting, interesting, and useful curated information to ” make things better!”

Slowly but surely, we can make the world a better place to live in.

—

Ads.

World’s best and largest online store. Over a million products to choose from.

Browse through interesting products and solutions below:

—

Start Your Farm: The Authoritative Guide to Becoming a Sustainable 21st Century Farmer

—

Compact Farms: 15 Proven Plans for Market Farms on 5 Acres or Less

—

The Joy of Keeping Farm Animals: Raising Chickens, Goats, Pigs, Sheep, and Cows (The Joy of Series)

—

Dirt to Soil: One Family’s Journey into Regenerative Agriculture

—

Biogas from Waste and Renewable Resources: An Introduction

—

—

—

The Farmer’s Office: Tools, Tips and Templates to Successfully Manage a Growing Farm Business

—

DJI Agras MG-1 Agriculture Spraying Drone with Battery Charger

—

—

💥Coral Conservation

Coral Reef Conservation (Conservation Biology)

—

Coral Reefs: Tourism, Conservation and Management (Earthscan Oceans)

—

—

💥Ilocos Books and Songs. Buy Online.

History of Ilocos: Volumes I and II

—

THE BEST OF ILOCANO SONGS: BUKROS SINGERS VOLUME 5

—

REGION I : Ilocos Norte, Abra, Ilocos Sur, Mountain Province, Benguet, La Union and Pangasinan

—

Orientation Guide to the Philippines Ilocos Region and the Ilocano Culture: Religion, Traditions, Family Life, Urban and Rural Populations, Geography, History, Economy, Society and Security

—

💥Immaculate Conception

The Dogma of the Immaculate Conception: History and Significance

—

Immaculate Conception and the Holy Spirit: The Marian Teaching of St. Maximilian Kolbe

—

St. Thomas Aquinas on Immaculate Conception of Mary

—

💥Business Franchising

Everything you love about Amazon.

—

The Franchise MBA: Mastering the 4 Essential Steps to Owning a Franchise

—

Franchise Your Business: The Guide to Employing the Greatest Growth Strategy Ever

—

Franchise Bible: How to Buy a Franchise or Franchise Your Own Business

—

💥 Confession

Confession. The Author discusses the moral and practical aspects of this sacrament in great depth.

—

7 key “secrets” or hidden truths about the great spiritual beauty, power and depth of Confession.

—

💥 Pornography

Your Brain on Porn: Internet Pornography and the Emerging Science of Addiction

—

The Porn Myth: Exposing the Reality Behind the Fantasy of Pornography

—

—

💥 Japan Justice System

The Japanese Way of Justice: Prosecuting Crime in Japan (Studies on Law and Social Control)

—

Comparative Criminal Justice Systems: A Topical Approach, 7th Edition

—

—

💥 Alaskan Sockeye Red Salmon

—

—

Wild Alaskan Sockeye Salmon: 6 Oz Dinner Fillets (Six 6 oz dinner fillets)

—

Lose Weight Naturally and Effectively by Activating Your Metabolic System

—

25 FREE Amazon Kindle Mystery and Suspense eBooks. Take Your Pick or Take Them All!

—

Follow JcGreg Solutions Social Media Sites.

—

🔥🔥🔥 B2B Solutions

Cost Saving and Income Generating B2B Solutions Below:

—

Kinetic Hydro Turbines with power from 0.2 to 8kw. Driven by the flow speed, they are intended to be used submerged in channels, big water pipes and rivers with NO HEAD.

https://www.bloglovin.com/@gregoriojess/kinetic-hydro-turbines

—

Aerobic Digestion, Biogas, Biomethane, and W2E.

We do biogas plant construction. Power and waste treatment solutions for any kind of organic waste. Turn it into additional profit.

Small and compact automated anaerobic digester

Medium to large automated digester tank farm system, 100 to 2MWH power generation.

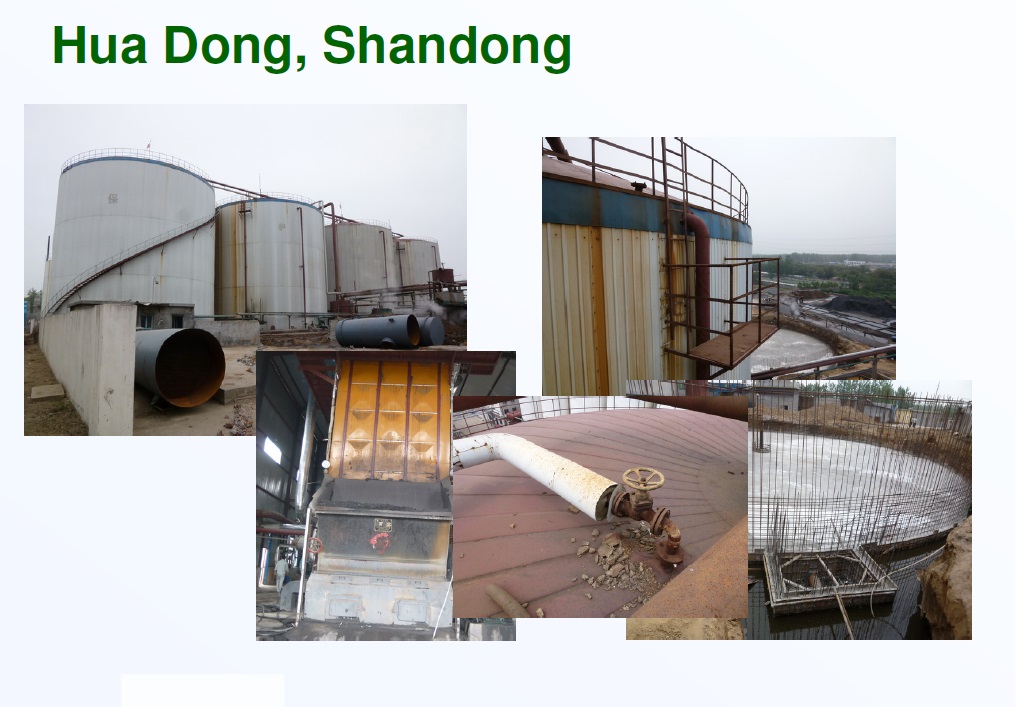

http://en.planet-biogas.com/references/

Large to super large lagoon type mixed and automated anaerobic digestion systems, 200 to 22MW power generation.

https://jcgregsolutions.wordpress.com/2019/07/23/anaerobic-treatment-of-ethanol-effluent/

Reference Biogas Plant in the Philippines:

We’ve done over 400+ biogas plant around the world.

We do Build-Operate-Transfer (BOT) for W2E of 500KWe (and above) from waste conversion. We can assess, validate, verify project sustainability and feasibility, design a matched system for your kind and quantity of substrate, and offer a corresponding solid or liquid waste tank or lagoon based biogas or biomethane plant. Email us your interest on this regard. We will send you a preliminary questionnaire that you need to fill up for us to qualify potential benefits.

Jess C. Gregorio

Philippine Sales Manager

PlanET Biogas Global GmbH

Email: j.gregorio@planet-biogas.com

Email: gregoriojess@yahoo.com

Website: http://en.planet-biogas.com/

—

Rooftop Domestic Solar Power and Solar Powered Water Pump for Irrigation

https://jcgregsolutions.wordpress.com/2017/07/08/rooftop-solar-power-installation/

—

Boiler Blowdown Heat Recovery and Cost Saving Project

https://jcgregsolutions.wordpress.com/2017/07/11/blowdown-heat-recovery-systems-for-boilers/

—

SCADA (Supervisory Control And Data Acquisition)

https://jcgregsolutions.wordpress.com/2018/01/14/on-scada-and-gateway-rtus

—

Mini Biodiesel Plant from Used Cooking Oil

https://jcgregsolutions.wordpress.com/2017/12/08/farm-based-biodiesel-manufacturing/

—

Smart WIFI Remote Camera Viewing and Control. Integral Two Way Audio for Condos, Offices, Stores, and Homes.

Biogas offers a number of outstanding interactions especially with regard to the methods of livestock farming. Pig and poultry farmers, in particular, need considerable amounts of heat. Most of the CHP’s thermal energy can be used for local heat concepts to replace costly fossil fuels or granting the operator additional income by selling it to e.g. public buildings like hospitals, swimming pools or retirement houses. Another way is the addition of a dryer to the biogas plant set up. There are several containerized PlanET plug-and-play solutions for easy integration into existing or newly designed concepts.

Read more. Learn more. Click here.

—

Ads.

Need to buy something online? Shop and buy from the world’s best and largest store. Over a million products to choose from. Check it out.

These ads contain affiliate links with corresponding affiliate commission for an Amazon Associate. There is no extra cost for you on this.

—

💥 Top 10 Most Subscribed Magazines. Buy Online.

—

—

—

—

—

—

—

—

—

—

💥 Portable Solar Power Units. Have power anywhere you go. Shop online. Buy onine.

Boss Watt Tripod Panel – 50W SunPower Solar Panel with Detachable Stand and MC4 Extension Cord

—

SunPower® 50 Watt Flexible Monocrystalline High Efficiency Solar Panel

—

[30W Panel Foldable] HKYH Solar Panel Lighting Kit, Solar Home DC System Kit, USB Solar Charger with 4 LED Light Bulb as Emergency Light and 5 Mobile Phone Charger/5V 2A Output Can Charge Power Bank

—

BAXIA TECHNOLOGY Solar Lights Outdoor,Wireless 28 LED Solar Motion Sensor Lights,Waterproof Security Lights for Outdoor Wall,Back Yard,Fence,Garage,Garden,Driveway(400LM,4 Packs)

—

ECO-WORTHY 12 Volts 5 Watts Portable Power Solar Panel Battery Charger Backup for Car Boat Batteries

—

25000mAh Solar Charger ADDTOP Portable Solar Power Bank with Dual 2.1A Outputs Waterproof External Battery Pack Compatible Most Smart Phones, Tablets and More (92.5Wh 2018 Upgraded)

—

A Complete Guide to the Installation of Off-Grid PV Solar Power Systems

—

Solar Charger 15000mAh, Elzle Portable Solar Power Bank Dual USB Backup Battery Pack Charger, Outdoor Solar Phone External Battery Charger with 6 Led Flashlight for iPhone Series, Smart Phone, More

—

PowerFilm 30W Foldable Solar Panel with Goal Zero Yeti Adapter

—

DIY Solar Projects

—

💥 Health Inducing Guides and Products. Shop Online. Buy Online.

How Not to Die: Discover the Foods Scientifically Proven to Prevent and Reverse Disease

—

Lose Weight Naturally and Effectively by Activating Your Metabolic System

—

JcGreg Solutions (No.58 on global site ranking) delivers interesting information and B2C/B2B products to make things better.

Follow and subscribe to any of my 16 JcGreg Solutions Social Media Sites. Interesting topics and life hacks on auto-update.

—

Below are compiled domestic solutions that will create opportunities for cost savings, make waste a resource, additional profit from nothing, solve a challenge, and speed up process of correction and recovery.

Thank you for your continuing patronage.

—

Turn Wastewater Lagoons Into Goldmines.

—

Cost Saving and Planet Friendly Technologies. When Green Turns into Gold.

https://jcgregsolutions.wordpress.com/2018/08/02/cost-saving-and-planet-friendly-technologies/

—

Lack of Irrigation Caused by Drought (El Nino) is an Easy Challenge.

—

Your Foodwaste. Your Power.

—

Solar Panel on Your Rooftop. Free Energy.

https://jcgregsolutions.wordpress.com/2017/07/08/rooftop-solar-power-installation/

—

The Magazine of Cancer Status and Cure Updates

—

Do you have a Genius at home?

—

El Nino. Get the sun to pull those water up.

https://jcgregsolutions.wordpress.com/2018/01/14/on-running-a-water-pump-without-operating-cost/

—

Biogas. Expertise and Experience is your Best Option.

—

Generate 100KWe on your small livestock farm animal manure.

—

Don’t burn you agri trash! Have 100KWe from it.

—

You just don’t know how much money you throw on your boiler continuous blowdown

https://jcgregsolutions.wordpress.com/2017/07/11/blowdown-heat-recovery-systems-for-boilers/

—

SCADA. See and Analyze All That Matters.

https://jcgregsolutions.wordpress.com/2018/01/14/on-scada-and-gateway-rtus

—

Used Cooking Oils to Biodiesel. It is like having your own oil refinery.

https://jcgregsolutions.wordpress.com/2017/12/08/farm-based-biodiesel-manufacturing/

—

How to turn waste into resources.

https://jcgregsolutions.wordpress.com/2018/01/18/on-turning-organic-waste-into-non-pollutant/

—

Hands on Cleaning of Rivers, Bays, and Seas.

—

Palm Oil Mill into a Renewable Power Plant

—

Where to find the Best Online Deals, Promos, and Products.

—

How to avoid shopping stress especially during holidays and sudden needs.

—

Great Knowledge & Information Blog to follow.

—

Subscribe to an Interesting and Useful Life Hack Blogsite.

https://jcgregsolutions.wordpress.com/

—

Need to buy something online? Shop and buy from the world’s best and largest store. Over a million products to choose from. Check it out.

—

On Philippine Politics

Lessons Learned from the Recent Election 2019.

https://jcgregsolutions.wordpress.com/2019/05/15/lessons-learned-from-the-recent-election-2019/

Why Philippine 2019 Election, and Previous Elections, are Exercises in Futility.

This post contain affiliate links. As an Amazon Associate I earn from qualifying purchases. There is no additional cost to you.

—

Amazon Kindle Books Unlimited Membership. Bring your own book library wherever you go. Download millions of books on any device.

https://jcgregsolutions.wordpress.com/2020/01/30/unlimited-access-to-millions-of-books/

—

Protect Yourself From 2019-nCov Virus And Volcanic Ash Inhalation

Disclaimer:

There are no current vaccines, pills, potions, lotions, lozenges or other prescription or over-the-counter products available to treat or cure coronavirus disease 2019 (COVID-19). For official information and guidance, please refer to Centers for Disease Control and Prevention (CDC) website below:

https://www.cdc.gov/coronavirus/2019-ncov/index.html

—

Click any department below and choose whatever you need from over 353 Million products on stock.

What surprised me is that the increase in bankruptcies worldwide stems almost solely from an increase in formal bankruptcy proceedings in China. The 10% increase worldwide for 2018 was due almost entirely to a 60% increase in China bankruptcies. In 2019, the projection is for a worldwide increase of 6%, with China once again by far the highest in the world with a projected 20% increase.

The message of this post is that the danger of paying and getting nothing from your Chinese supplier comes from BOTH private companies and from SOEs. Based on my own experience, I see the SOEs as a greater danger. When you get an offer from a Chinese supplier that seems “too good to be true,” it is. Extreme care is required.

— — —

Follow a Knowledge & Information Blog Bank.

— — —

Ads.

One world. One life. Make things better.

Below are personally selected sets of products and solutions to make things better. Each blog that I post has different sets. Check it out, I highly recommend these for you. The ads contain an affiliate link with corresponding small affiliate commission for me when you buy it online through Amazon links below. There is no extra cost for you on this. Thank you in advance for your continuing patronage.

Hoping to add more sunshine and fun in your life.

—

DualShock 4 Wireless Controller for PlayStation 4 – Crystal

—

—

PSVR Aim Controller – PlayStation 4

—

Hard Travel Case for Sony PlayStation 4 Pro Console + PlayStation VR PSVR Launch Bundle by co2CREA

—

Sony PlayStation 4 Gold Wireless Headset 7.1 Surround Sound 500 Million – Nintendo Wii; GameCube

—

—

—

—

Anki Cozmo, A Fun, Educational Toy Robot for Kids

—

Learning Resources Botley the Coding Robot Activity Set, Code for Kids – Toy of The Year Finalist

—

Wonder Workshop Dash Robot with Wonder Workshop Dash & Dot Robot Wonder Pack Bundle

—

SELFON 2.4GHz 300M USB 2.0 WiFi Range Extender Wireless Repeater Router Signal Booster Signal Amplifier (black)

—

Greendream PIXLINK WR03 WiFi Repeater Wireless Range Extender Booster 300Mbps

—

yinboti WiFi Extender Repeater – Small WiFi Booster Up to 300Mbps with Ethernet RJ45 WLAN Port

—

WiFi Range Extender, ELEGIANT 1200Mbps Wireless WiFi Repeater Signal Amplifier Booster Supports Router Mode/Repeater/ Access Point, 360 degree WiFi Coverage

—

Simple WiFi Long Range Hotspot Repeater

—

Sunhans Outdoor WiFi Signal Booster 20W 2.4Ghz 43dBm High Power Wireless Outdoor Amplifier Wifi Signal Bi-directional FPV Drone

—

Xiaomi Mi Smart Home WiFi Repeater 2 300M Amplifier Extender Signal Boosters USB WiFi Wireless Universal Router

—

USDA Choice Beef Sirloin Cap Steak – 6 oz – Steaks for Delivery

—

USDA Choice Beef Top Sirloin Center Cut Steak – 6 oz – Steaks for Delivery

—

The Texas Steak Warehouse

USDA Choice Beef Top Sirloin Center Cut Steaks – 8 oz – Steaks for Delivery

—

The Texas Steak Warehouse

Certified Hereford USDA Choice Top Sirloin Steak – 8 oz – Steaks for Delivery

—

Texas Metro Center Cut Filet Mignon Steak – 5 oz – Steaks for Delivery

—

Certified Hereford USDA Choice NY Strip Steak – 8 oz – Steaks for Delivery

—

The Future of Eye Wear. Calls, Music, and Apps with just a Tap.

https://jcgregsolutions.wordpress.com/2019/01/21/the-future-of-smart-eye-glasses/